Getting a Torchmate 4400 running

- SegoMan DeSigns

- 4 Star Member

- Posts: 952

- Joined: Sat Jan 06, 2018 4:45 pm

Re: Getting a Torchmate 4400 running

Do you have any contact information on the original owner? They may have the dongle in a drawer somewhere or the original bill of sale that has a dongle number on it. When you approached T M did you have a serial number handy and ask them about the original sale information?

Like David says it sounds like the quote was for the top of the line software. Your machine may have had the premium softtwre or it could have been the basic.

Here is a link for the dongle replacement:

https://www.torchmatestore.com/torchmat ... _3272.html

Like David says it sounds like the quote was for the top of the line software. Your machine may have had the premium softtwre or it could have been the basic.

Here is a link for the dongle replacement:

https://www.torchmatestore.com/torchmat ... _3272.html

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

I do, but unfortunately they can't find it. The current person is new and has no clue where anything for the table went when the previous person left.

QCAD and Sheetcam should be fine for getting me going. Just need to get the ohmic THC feature resolved.

QCAD and Sheetcam should be fine for getting me going. Just need to get the ohmic THC feature resolved.

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 9854

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Getting a Torchmate 4400 running

I purchased a QCad license earlier this year to check it out, but really haven't had the time to try it too much yet. I'll need to go into the preference settings to set the units to decimal and not the ft/inches as currently displayed on the screen. I think I paid around $50 US for the QCad Professional perpetual license.

David

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

That's funny. That is the first thing I did when I tried the trial...the ft/in setting is probably standard for architectural, but was very confusing.

So...a little more success. The software seemed somewhat buggy running on the original Shuttle PC that ships with the TM4400. So I utilized a newer Dell with an NVMe drive in it, clean Win10 Pro install, clean install of the QCAD trial and SheetCAM trial, and the Torchmate VMD software. Because I probably won't be using it, I didn't bother with installing the TM CAD/CAM software. Other than having the computers IP set wrong so it wouldn't talk to the VMD, it loaded right up and is happily talking to the VMD now.

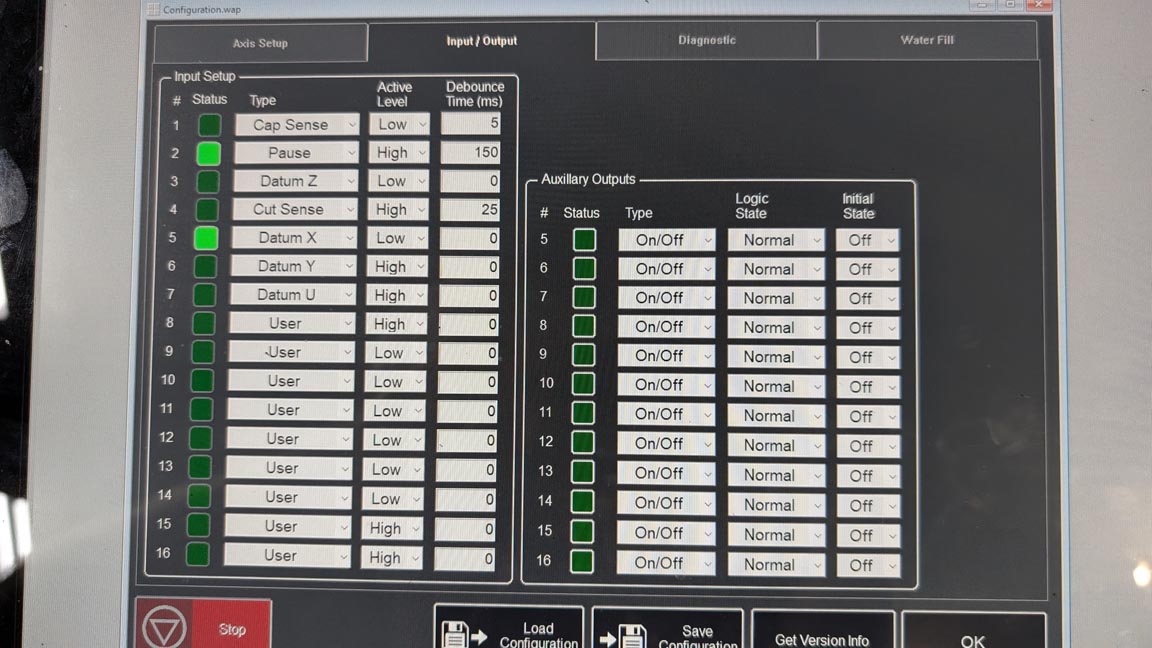

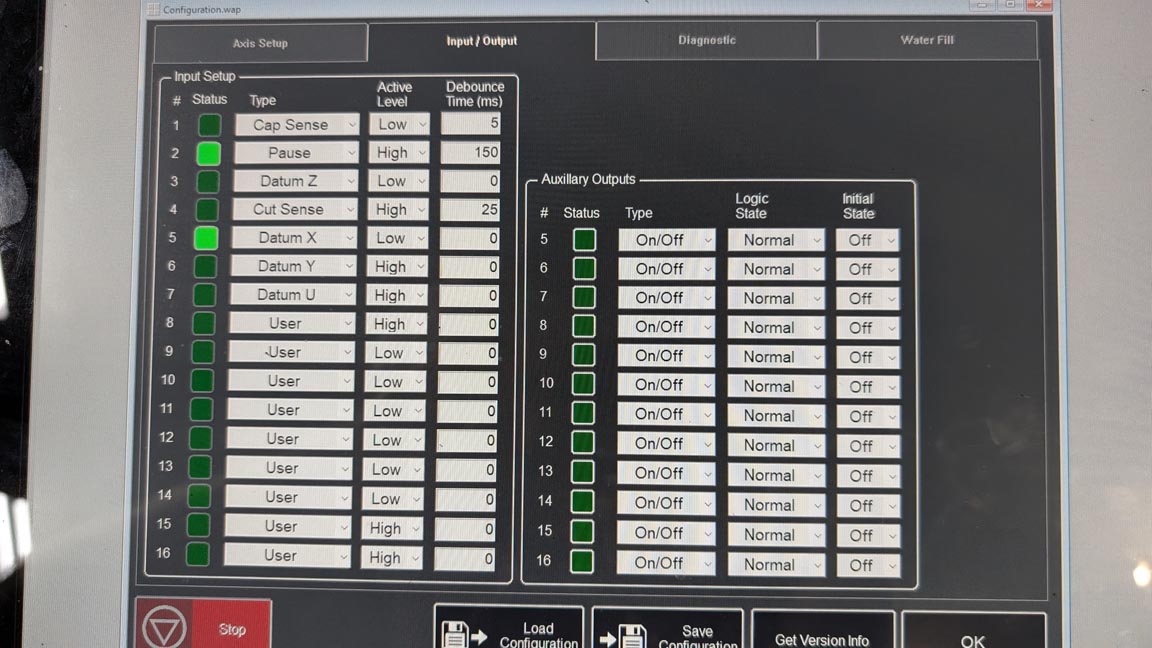

Logging in as Admin and going to Configuration > Input/Output and setting the status for Aux outputs #8 to on, I could hear a relay click and when jogging the torch down to the metal plate, IHC Detected shows up, and cycles on and off properly. When I turn the Aux output #8 back off, the VMD software won't detect the plate when I hit Datum. Even more strange, the Z axis seems to move backwards. Z+ goes down, Z- goes up, so it moves up vertically until the carriage tops out and will sit there making noises until I stop it (which I do quickly). I've glanced around in the software and can't see how to flip the axis functionality.

Likewise, I'm not sure why IHC doesn't work when trying to set Datum, but does during diagnostics. Here's a copy of the Input/Output settings that I have (as loaded from the default 4400.ini config file).

Is there something obvious that stands out that would explain why IHC isn't functioning as it should and why the Z axis is running backwards?

I'm so close to cutting parts! Exciting...

So...a little more success. The software seemed somewhat buggy running on the original Shuttle PC that ships with the TM4400. So I utilized a newer Dell with an NVMe drive in it, clean Win10 Pro install, clean install of the QCAD trial and SheetCAM trial, and the Torchmate VMD software. Because I probably won't be using it, I didn't bother with installing the TM CAD/CAM software. Other than having the computers IP set wrong so it wouldn't talk to the VMD, it loaded right up and is happily talking to the VMD now.

Logging in as Admin and going to Configuration > Input/Output and setting the status for Aux outputs #8 to on, I could hear a relay click and when jogging the torch down to the metal plate, IHC Detected shows up, and cycles on and off properly. When I turn the Aux output #8 back off, the VMD software won't detect the plate when I hit Datum. Even more strange, the Z axis seems to move backwards. Z+ goes down, Z- goes up, so it moves up vertically until the carriage tops out and will sit there making noises until I stop it (which I do quickly). I've glanced around in the software and can't see how to flip the axis functionality.

Likewise, I'm not sure why IHC doesn't work when trying to set Datum, but does during diagnostics. Here's a copy of the Input/Output settings that I have (as loaded from the default 4400.ini config file).

Is there something obvious that stands out that would explain why IHC isn't functioning as it should and why the Z axis is running backwards?

I'm so close to cutting parts! Exciting...

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

I just found this and will have a look, but I wouldn't think I should need to make that kind of change. None of the wiring looks modified that I can tell so I don't think someone cut wires and flipped them.

https://torchmate.com/driver-software/I ... ftware-V-3

https://torchmate.com/driver-software/I ... ftware-V-3

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

I think that link is for a much older version of TM or for a different machine. I can't find anything like that in the current setup, at least not in VMD.

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 9854

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Getting a Torchmate 4400 running

You may just have to go back to first principles and trace out the wiring system to figure out how it works. The only one that I know of on this forum with a TM table is Ben. I have never heard him talk much about his actual table, but he really likes the TMCad software for all of his professional design tracing. You could try reaching out to Ben at the link below via PM.

https://www.plasmaspider.com/memberlist ... ile&u=2646

David

https://www.plasmaspider.com/memberlist ... ile&u=2646

David

- ben de lappe

- 4 Star Elite Contributing Member

- Posts: 1287

- Joined: Mon Aug 03, 2009 9:37 am

- Location: North Mississippi

Re: Getting a Torchmate 4400 running

I saw this thread and wanted to help but my setup is a TM 3 with blue screen AVHC and old style motor control with TM4 driver software. Unfortunately I have no experience whatsoever with VMD or any of the newer hardware/software.

If you happen to be on Facebook check out this group. https://www.facebook.com/groups/128042524552012

There's a lot of TM pros there and I bet they'll be able to help.

If you happen to be on Facebook check out this group. https://www.facebook.com/groups/128042524552012

There's a lot of TM pros there and I bet they'll be able to help.

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

A Lincoln Electric tech is going to take a remote look at the VMD software, hopefully tomorrow.

I got a quote for TM CAD Lite, $675. Hopefully QCAD and SheetCAM will do what I need

I got a quote for TM CAD Lite, $675. Hopefully QCAD and SheetCAM will do what I need

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

Connected with an LE tech and got him remote access to my machine. We did some testing on the Z axis issue and he was able to make a change that inverted just the Z axis function, so that is operating normally.

Then we started working on the Z axis datum issue. He sent me a decent troubleshooting document (why don't they just make them all publicly available?) and working through that I narrowed down the issue to the torch carriage itself. After unbolting some cable management clips, I found one of two wires in the Molex connector for the top Z axis datum switch had pulled out of its crimp. Assuming that switch works in concert with the bottom Z axis datum switch, that would certainly be causing problems. Now to find a set of tools to extract the little pin so I can re-crimp and solder it....

Then we started working on the Z axis datum issue. He sent me a decent troubleshooting document (why don't they just make them all publicly available?) and working through that I narrowed down the issue to the torch carriage itself. After unbolting some cable management clips, I found one of two wires in the Molex connector for the top Z axis datum switch had pulled out of its crimp. Assuming that switch works in concert with the bottom Z axis datum switch, that would certainly be causing problems. Now to find a set of tools to extract the little pin so I can re-crimp and solder it....

- SegoMan DeSigns

- 4 Star Member

- Posts: 952

- Joined: Sat Jan 06, 2018 4:45 pm

Re: Getting a Torchmate 4400 running

Your making headway, I have had molex crimp problems myself. I re-crimped then soldered in place. Use die electric silicone on all connects as well

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

Going to reinforce with heat-shrink tubing as well.

I noticed the Z axis screw appears to be bone dry. Should it be greased with the same grease as the gantry cassettes? Or does that run dry so it doesn't pick up grit from the torch operation.

I noticed the Z axis screw appears to be bone dry. Should it be greased with the same grease as the gantry cassettes? Or does that run dry so it doesn't pick up grit from the torch operation.

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

Grease for the Z axis screw?

So...the Z Datum issue seems to be resolved and the torch carriage seems happy. But...the Y axis is doing strange things. When I hit Datum, the gantry will move to the "front" of the table, stop, and then the right motor will start trying to move back, binding up the gantry and making bad noises. I pulled the covers off and if I run the gantry out and back in using the arrows on the screen, both the sensor indicator lights on the sensors themselves seem to turn on at exactly the same time. I found a doc about zeroing the gantry...working through that at the moment.

Went through that procedure and one of the sensor "stops", the movable block that the hall effect sensors sense for positioning, was out quite a bit. After some adjustment I got #6 and #7 indicators, U and Y axis, lighting up as close to each other as I can on the Inputs diagnostic screen. Still have the same issue when I try to Datum.

Curiously, the sensor on the right side of the table is not original and appears to be a different brand. I found the original sensor unscrewed but still under the cover. I hooked it back up but it is always tripped whenever any metal is near, including the nuts that hold it on, so obviously that sensor is defective. I tied it back out of the way.

Emailed LE tech...waiting for more help.

So...the Z Datum issue seems to be resolved and the torch carriage seems happy. But...the Y axis is doing strange things. When I hit Datum, the gantry will move to the "front" of the table, stop, and then the right motor will start trying to move back, binding up the gantry and making bad noises. I pulled the covers off and if I run the gantry out and back in using the arrows on the screen, both the sensor indicator lights on the sensors themselves seem to turn on at exactly the same time. I found a doc about zeroing the gantry...working through that at the moment.

Went through that procedure and one of the sensor "stops", the movable block that the hall effect sensors sense for positioning, was out quite a bit. After some adjustment I got #6 and #7 indicators, U and Y axis, lighting up as close to each other as I can on the Inputs diagnostic screen. Still have the same issue when I try to Datum.

Curiously, the sensor on the right side of the table is not original and appears to be a different brand. I found the original sensor unscrewed but still under the cover. I hooked it back up but it is always tripped whenever any metal is near, including the nuts that hold it on, so obviously that sensor is defective. I tied it back out of the way.

Emailed LE tech...waiting for more help.

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

Success! After LE Tech support told me which side was the Y and U axis, I noticed they were backwards. I swapped the cables under the table and now the machine runs Datum without issues.

Up next...figure out how to set the start point for a job. Right now, it wants to start so close to the edge of the table that it would cut it if I wasn't in dry-run mode. Now the "regular" user learning starts...

The first time I tried the dry run, the machine was very jerky. I noticed it defaulted to 260ipm for some reason. I set that to an arbitrary 100ipm and it runs nice and smooth. I'll be pulling up the Hypertherm cut tables and figure out how to get the cut speeds calibrated, in addition to using the test cut job.

Up next...figure out how to set the start point for a job. Right now, it wants to start so close to the edge of the table that it would cut it if I wasn't in dry-run mode. Now the "regular" user learning starts...

The first time I tried the dry run, the machine was very jerky. I noticed it defaulted to 260ipm for some reason. I set that to an arbitrary 100ipm and it runs nice and smooth. I'll be pulling up the Hypertherm cut tables and figure out how to get the cut speeds calibrated, in addition to using the test cut job.

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

I watched the "Quick Hits: Using the Shape Library" video that LE has on Youtube. I had already been doing exactly what the guy shows in the video but the Set Plate Origin button is greyed out. I can't figure out why. Do you guys know?

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

Figured it out...need to "reset" the running cut program.

I ran the sample cut program that cuts a square with a hole in the middle. It worked great except for the bevel created. The inside hole also had a strange bevel to it. If I didn't know better, it almost looks like the hole was created by a large drill bit that was at an angle. The bevel changed as the torch moved around the hole.

It was so gratifying to watch the machine do its thing! The rest is just learning the software and customizing the cut parameters...and buy a new set of consumables.

I ran the sample cut program that cuts a square with a hole in the middle. It worked great except for the bevel created. The inside hole also had a strange bevel to it. If I didn't know better, it almost looks like the hole was created by a large drill bit that was at an angle. The bevel changed as the torch moved around the hole.

It was so gratifying to watch the machine do its thing! The rest is just learning the software and customizing the cut parameters...and buy a new set of consumables.

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

I assumed that the VMD is able to control amperage of the FlexCut 80 machine...I'm wondering if that is not the case, but the operators manual doesn't actually say one way or another. Are the plate settings telling me how many amps I need to manually set the plasma machine to? Or is it telling the plasma machine how many amps to run at automatically?

-

weldguy

- 4.5 Star Elite Contributing Member

- Posts: 2168

- Joined: Fri Apr 17, 2009 11:48 am

Re: Getting a Torchmate 4400 running

Glad to hear your making some progress and getting excited!

If it was a Hypertherm plasma it would be easy to tell but with your Flexcut it's hard to say whether or not your plasma cutters amperage is controlled through the software. It should be pretty easy to determine that with a simple straight cut at the lowest amperage and another at the highest amperage. You will be able to tell from the sight and sound alone between the 2 cuts.

Curious what you find out.

If it was a Hypertherm plasma it would be easy to tell but with your Flexcut it's hard to say whether or not your plasma cutters amperage is controlled through the software. It should be pretty easy to determine that with a simple straight cut at the lowest amperage and another at the highest amperage. You will be able to tell from the sight and sound alone between the 2 cuts.

Curious what you find out.

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

I noticed that the bevel on the test cut I did is the same direction no matter where it's at...makes me think the torch isn't exactly perpendicular to the cut surface. I'll be confirming that when I get home.

I'll try what you said too...and set it to 30A in software which won't pierce 1/4" plate...if it still blows through then no, the software can't control the amperage.

I'll try what you said too...and set it to 30A in software which won't pierce 1/4" plate...if it still blows through then no, the software can't control the amperage.

-

weldguy

- 4.5 Star Elite Contributing Member

- Posts: 2168

- Joined: Fri Apr 17, 2009 11:48 am

Re: Getting a Torchmate 4400 running

Could also be that the hole in the center of the nozzle where the arc is emitted through is no longer round, or the hole is blown out on 1 side. This can happen easily if the nozzle touches the material during cutting, or you have moist/dirty air supply, or you pierce cycle is too long and the arc starts to wander looking for material to conduct to.

- ben de lappe

- 4 Star Elite Contributing Member

- Posts: 1287

- Joined: Mon Aug 03, 2009 9:37 am

- Location: North Mississippi

Re: Getting a Torchmate 4400 running

Glad to see you're getting things sorted, great feeling as that happens.jlasater wrote: ↑Tue Aug 27, 2024 7:46 am If I didn't know better, it almost looks like the hole was created by a large drill bit that was at an angle. The bevel changed as the torch moved around the hole.

It was so gratifying to watch the machine do its thing! The rest is just learning the software and customizing the cut parameters...and buy a new set of consumables.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

Yeah...that diagram is in the 4xxx manual. The unfortunate part of having a day job is I can't run to the shop and check things until I get home! hah...the LE Tech asked if I had AVHC and other features turned on which I can't answer yet. Look forward to getting home

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

So...had some good success tonight! The project was cutting out a bunch of 1/4" plates that will be weights on the back of my Grasshopper 614 lawn tractor.

Once I figured out the Torchmate VMD2 post-processor was the ticket in SheetCAM, the Torchmate VMD program happily read the files and cut.

The big issue I was running into is regularly losing the cut, meaning the torch would go out. I have consumables on order, and everything else I can think of on the machine is ok, so hopefully that will fix the issue. I did notice that the torch tended to go out when moving right-to-left on the Y axis, rarely moving left-to-right. I slowed the cut speed clear down to 60ipm (120ipm is "optimal") but that didn't make any difference.

I'll be able to salvage a number of the incomplete cuts with a hand plasma torch.

Man...I am just STOKED to get a project cut on the machine. Overall getting it in service has been a lot of fun! And I appreciate all the help you guys have given me.

Once I figured out the Torchmate VMD2 post-processor was the ticket in SheetCAM, the Torchmate VMD program happily read the files and cut.

The big issue I was running into is regularly losing the cut, meaning the torch would go out. I have consumables on order, and everything else I can think of on the machine is ok, so hopefully that will fix the issue. I did notice that the torch tended to go out when moving right-to-left on the Y axis, rarely moving left-to-right. I slowed the cut speed clear down to 60ipm (120ipm is "optimal") but that didn't make any difference.

I'll be able to salvage a number of the incomplete cuts with a hand plasma torch.

Man...I am just STOKED to get a project cut on the machine. Overall getting it in service has been a lot of fun! And I appreciate all the help you guys have given me.

- ben de lappe

- 4 Star Elite Contributing Member

- Posts: 1287

- Joined: Mon Aug 03, 2009 9:37 am

- Location: North Mississippi

Re: Getting a Torchmate 4400 running

Great to see al the success!! Congratulations! Concerning loss of cut- Are you 100% sure that your air compressor is maintaining proper working pressure to the plasma unit according to specs throughout the entire cut?

-

jlasater

- 2 Star Member

- Posts: 89

- Joined: Thu Aug 08, 2024 5:41 pm

- Location: NE Oregon

- Contact:

Re: Getting a Torchmate 4400 running

The compressor is a 5hp Kellogg 2-stage with 80gal tank. Watching the air pressure on the FC80 unit, it doesn't really drop at all during the cut. I'll set up my phone to catch video though when I try it again tonight. There's a chance the PiP is kicking in because I've had issues with that before, and I just didn't see it.