Problems with Hypertherm Consumables...

-

ZTFab

- 1.5 Star Member

- Posts: 34

- Joined: Tue Jul 09, 2013 1:04 pm

Problems with Hypertherm Consumables...

Running a Powermax 65 with machine torch on an Arclight Dynamics 4x8 table.

I have an 80 Gallon Curtis compressor with auto drain feeding a Speedaire refrigerated drier through 3/4" Rapidaire piping, 2 coalescing filters and my shop is in Southern California. Dry, clean air is not a problem.

I have been having an issue with brand new, out of the package Hypertherm brand consumables. I am getting a skewed(angled) kerf on my parts as if the Torch is tilted to one side. I verify that the torch head is 90deg to the plate on both axes when I load each plate.

When I rotate the nozzle 180 degrees in the torch cap, the angle follows the nozzle. This is happening with every combination of used and new electrodes and/or swirl rings installed along with nozzles. It seems to be a problem with the nozzles regardless of the other parts. Both 45A and 65A are doing it but not every nozzle will. Usually about 2-3 out of a pack of 5.

As anyone else had this happen? Anything else I can check or change?

I have an 80 Gallon Curtis compressor with auto drain feeding a Speedaire refrigerated drier through 3/4" Rapidaire piping, 2 coalescing filters and my shop is in Southern California. Dry, clean air is not a problem.

I have been having an issue with brand new, out of the package Hypertherm brand consumables. I am getting a skewed(angled) kerf on my parts as if the Torch is tilted to one side. I verify that the torch head is 90deg to the plate on both axes when I load each plate.

When I rotate the nozzle 180 degrees in the torch cap, the angle follows the nozzle. This is happening with every combination of used and new electrodes and/or swirl rings installed along with nozzles. It seems to be a problem with the nozzles regardless of the other parts. Both 45A and 65A are doing it but not every nozzle will. Usually about 2-3 out of a pack of 5.

As anyone else had this happen? Anything else I can check or change?

-

muzza

- 4 Star Member

- Posts: 1460

- Joined: Wed Feb 04, 2009 5:35 pm

Re: Problems with Hypertherm Consumables...

Have you physically stopped your machine and measured your pierce and cut heights to make sure your heights are true. One low pierce is enough to damage a nozzle.

Is it touch and go? the material isn't flexing and coming back up to give you a false height reading?

Also you are using a machine torch, are you using a machine shield, not a hand held shield?

Murray

Is it touch and go? the material isn't flexing and coming back up to give you a false height reading?

Also you are using a machine torch, are you using a machine shield, not a hand held shield?

Murray

-

B Holmes

- 2 Star Member

- Posts: 85

- Joined: Mon Aug 06, 2012 9:29 pm

Re: Problems with Hypertherm Consumables...

Does the nozzle orifice still look concentric, or is it blown out?

5 x 10 Air bladder water table

Precision plasma HDB gantry

CandCnC 620-4 Bladerunner

Feather touch ohmic plate sensing

Hypertherm Powermax 65

2015 Autocad lt

Sheetcam

Mach 3

Central California

Precision plasma HDB gantry

CandCnC 620-4 Bladerunner

Feather touch ohmic plate sensing

Hypertherm Powermax 65

2015 Autocad lt

Sheetcam

Mach 3

Central California

-

ZTFab

- 1.5 Star Member

- Posts: 34

- Joined: Tue Jul 09, 2013 1:04 pm

Re: Problems with Hypertherm Consumables...

muzza wrote:Have you physically stopped your machine and measured your pierce and cut heights to make sure your heights are true. One low pierce is enough to damage a nozzle.

Is it touch and go? the material isn't flexing and coming back up to give you a false height reading?

Also you are using a machine torch, are you using a machine shield, not a hand held shield?

Murray

Pierce and cut heights are optimal. There are no pierce problems or damage to the nozzles. The orifice looks to be perfect but is cutting at an angle and only changes when the nozzle is rotated or changed out.

My table cuts beautifully for sheets of material at a time if/when I get a good nozzle. This happens when I go to change consumables and pull a brand new nozzle from the package...instantly angled cuts right after plenty of good parts.

I've been running this table for a year and this has only started happening in the last few weeks.

- tnbndr

- 4.5 Star Elite Contributing Member

- Posts: 1688

- Joined: Mon Jan 09, 2012 4:30 pm

- Location: New Berlin, WI

- Contact:

Re: Problems with Hypertherm Consumables...

Are you sure they are Hypertherm consumables and not imitations packaged to look like Hypertherm? I have heard that is an issue.

Dennis

LDR 4x8, Scribe, DTHCIV

Hypertherm PM45, Macair Dryer

DeVilbiss Air America 6.5HP, 80Gal., 175psi, Two Stage

16.9scfm@100psi, 16.0scfm@175psi

Miller 215 MultiMatic

RW 390E Slip Roll (Powered)

AutoCAD, SheetCAM, Mach 3

http://ikescreations.com

LDR 4x8, Scribe, DTHCIV

Hypertherm PM45, Macair Dryer

DeVilbiss Air America 6.5HP, 80Gal., 175psi, Two Stage

16.9scfm@100psi, 16.0scfm@175psi

Miller 215 MultiMatic

RW 390E Slip Roll (Powered)

AutoCAD, SheetCAM, Mach 3

http://ikescreations.com

-

ZTFab

- 1.5 Star Member

- Posts: 34

- Joined: Tue Jul 09, 2013 1:04 pm

Re: Problems with Hypertherm Consumables...

tnbndr wrote:Are you sure they are Hypertherm consumables and not imitations packaged to look like Hypertherm? I have heard that is an issue.

I buy my consumables from either Hypermax Online or from my local Praxair and they all come in Genuine Hypertherm packaging with Hypertherm Laser etching on each part so I hope that's not the case.

-

jimcolt

- 5 Star Elite Contributing Member

- Posts: 3087

- Joined: Mon Jul 20, 2009 11:18 pm

- Location: North Carolina

Re: Problems with Hypertherm Consumables...

I'm not saying that we never have defects, but the fact that more than one from a 5 pack of nozzles is certainly something we never hear. Any chance you can take some good focused, close up pictures of a nozzle that immediately showed sever bevel angles? Can you provide (take torch apart and read the numbers) the part numbers of each part (swirl ring, electrode, nozzle, retaining cap and shield?

Have you changed the swirl ring or the retaining cap with new? These parts eventually wear out, with the first symptom being bad angularity.

Can you show some pics of the cuts you are describing?

Jim Colt Hypertherm

Have you changed the swirl ring or the retaining cap with new? These parts eventually wear out, with the first symptom being bad angularity.

Can you show some pics of the cuts you are describing?

Jim Colt Hypertherm

-

metalworxfabricators

- 1.5 Star Member

- Posts: 39

- Joined: Thu Jan 03, 2013 10:32 am

- Location: Waxahachie, Texas

Re: Problems with Hypertherm Consumables...

When you bought your table did Arclight provide you with a couple CD's. If so one CD has lots of helpful tutorials on it. It has probably 10 or so tutorials dealing in length with plasma cutters from a-z. There is a lot to watch and digest but, I have found these tutorials as well as those done by Scott @ Arclight in their shop very helpful. As you probably already know Scott @ Arclight is nearly always available if the tutorials don't help. Try the tutorials. There is a wealth of information in them.

Best of luck,

Metalworx Fabricators

Arclight Pro 9600

Hypertherm Powermax 45

Best of luck,

Metalworx Fabricators

Arclight Pro 9600

Hypertherm Powermax 45

Metalworx Fabricators

ArcLight Dynamics

Hypertherm Powermax 45

ArcLight Dynamics

Hypertherm Powermax 45

-

Stout

- 3 Star Elite Contributing Member

- Posts: 255

- Joined: Wed Apr 29, 2009 8:14 am

- Location: Helotes, TX

Re: Problems with Hypertherm Consumables...

Change the retaining cap. Seen it before but don't know why it happens.

Actually just happened yesterday. New nozzle and electrode, and still getting an angled cut that is most noticeable on .8125" holes in .500 mild steel. Changed the swirl ring and no joy. Changed the retaining cap, problem solved.

Actually just happened yesterday. New nozzle and electrode, and still getting an angled cut that is most noticeable on .8125" holes in .500 mild steel. Changed the swirl ring and no joy. Changed the retaining cap, problem solved.

Victor Simonis

Grey Forest MetalCraft

Helotes, TX 78023

210-872-2622

Sector Technologies Photon 5x10 water table machine with Hypertherm Micro Edge Controller, Powermax 105

Grey Forest MetalCraft

Helotes, TX 78023

210-872-2622

Sector Technologies Photon 5x10 water table machine with Hypertherm Micro Edge Controller, Powermax 105

-

ZTFab

- 1.5 Star Member

- Posts: 34

- Joined: Tue Jul 09, 2013 1:04 pm

Re: Problems with Hypertherm Consumables...

Stout wrote:Change the retaining cap. Seen it before but don't know why it happens.

Actually just happened yesterday. New nozzle and electrode, and still getting an angled cut that is most noticeable on .8125" holes in .500 mild steel. Changed the swirl ring and no joy. Changed the retaining cap, problem solved.

Awesome, thanks.

I ordered all new front end consumables for my torch.

This has been driving me nuts and it's to the point that I can't even cut parts now because no combination of my current consumables will correct it.

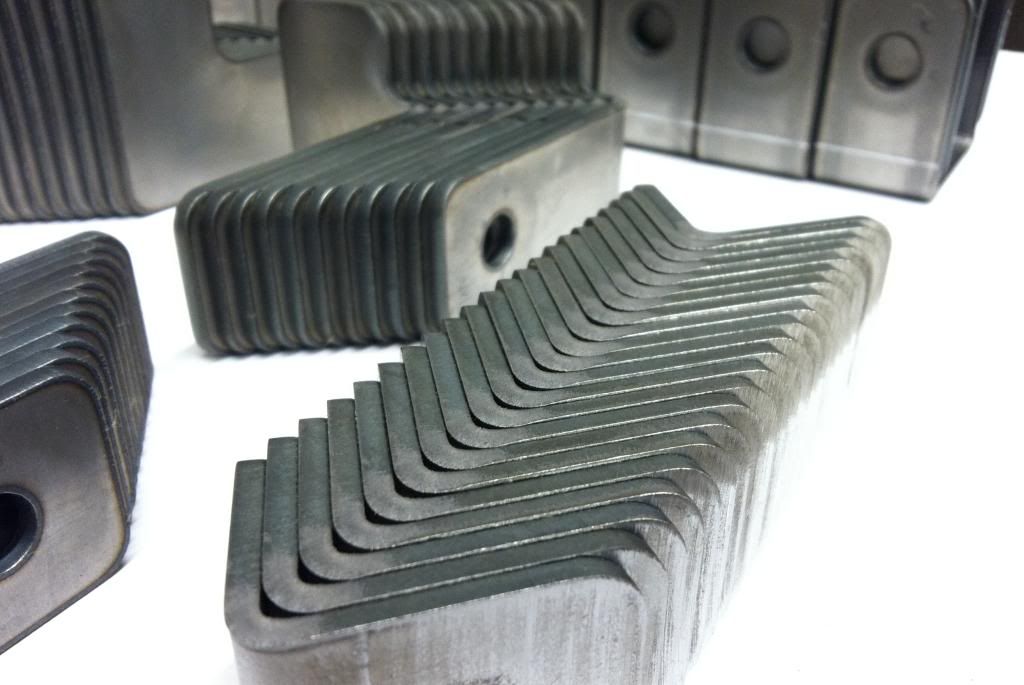

I've gone from cutting parts like this;

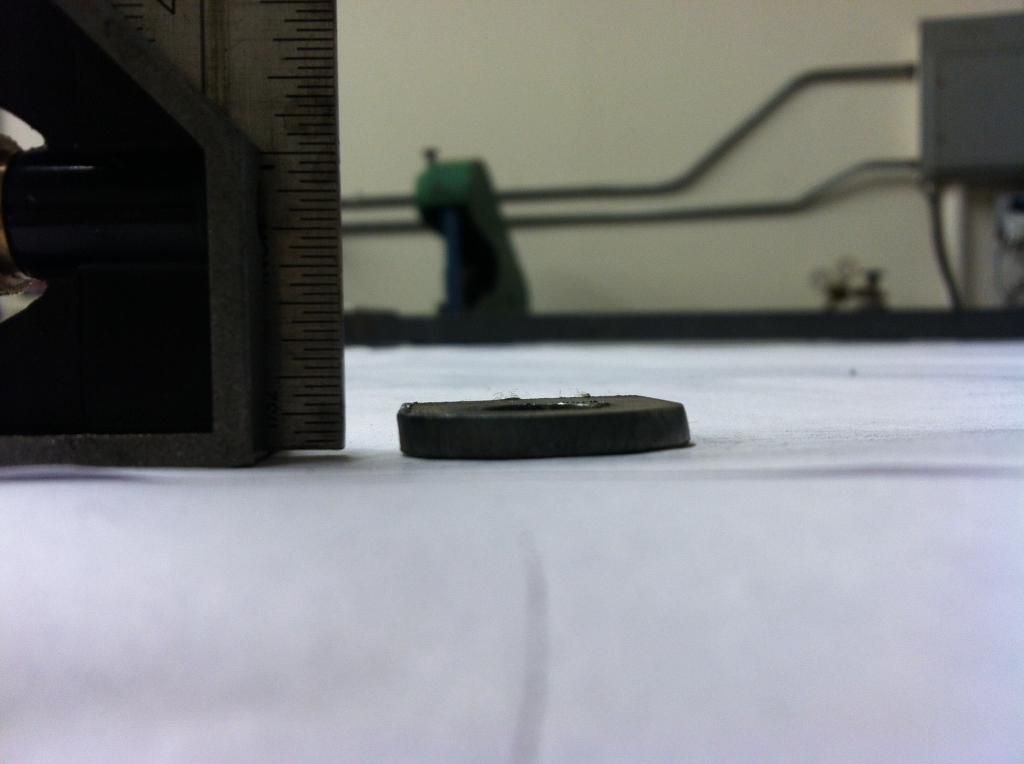

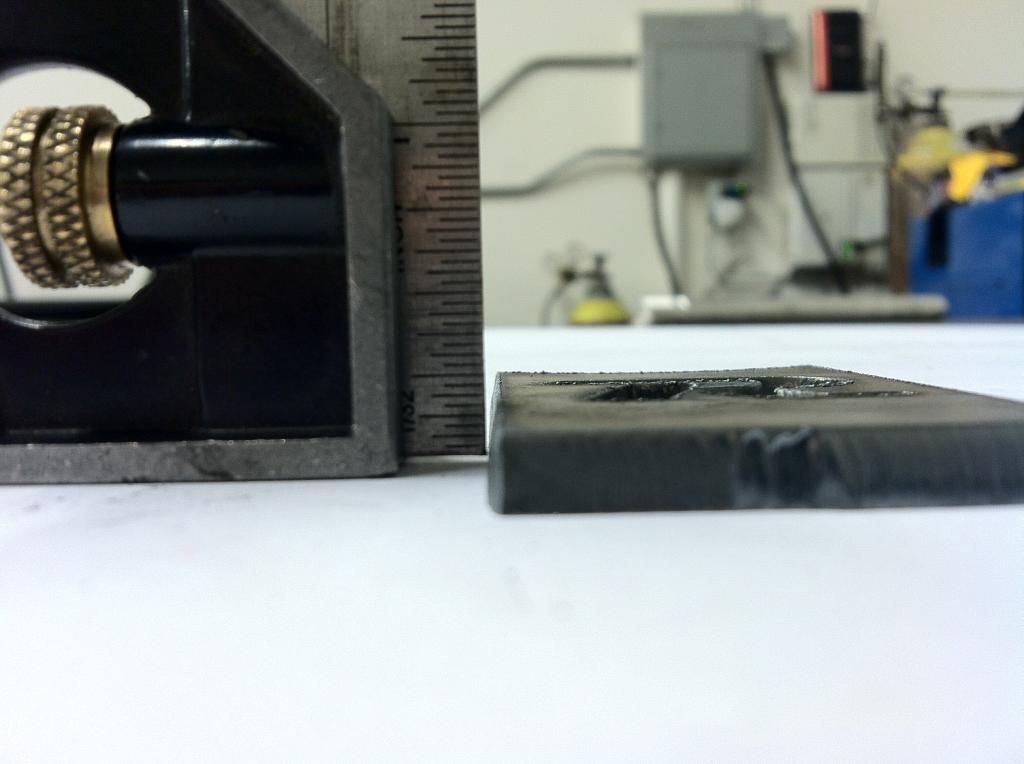

To cutting parts like this;

-

Brand X

- 3.5 Star Member

- Posts: 511

- Joined: Wed Apr 23, 2014 2:48 pm

Re: Problems with Hypertherm Consumables...

I would guess with the extra squeeze the shield makes, if damaged it would show right up in cut quality. The 65 amp consumables normally do a excellent job on 0.500 MS .. Looked at a ton of it my friend cut on his table.. Paul, be sure to post if the fix is in...

PS-nice work as always..

PS-nice work as always..

-

Brand X

- 3.5 Star Member

- Posts: 511

- Joined: Wed Apr 23, 2014 2:48 pm

-

ZTFab

- 1.5 Star Member

- Posts: 34

- Joined: Tue Jul 09, 2013 1:04 pm

Re: Problems with Hypertherm Consumables...

UPDATE:

Ok, so far I am happy to report that changing out the retaining cap seems to have solved the problem.

I just cut some 3/16" HRPO and it cut great.

I also cut a piece of 3/8" HRS and it was probably the best cut I've ever had on that thickness.

I still don't know what would/could go wrong with the retaining cap to warrant replacement? There is no damage, plugged orifices, or signs of wear that I can see???

Either way, it's a relatively cheap fix seeing as how I got a year of cutting out of the first cap. Thanks for the tip Stout. I owe you one.

Here are the 3/16" parts. They are only 1.5" x 2"

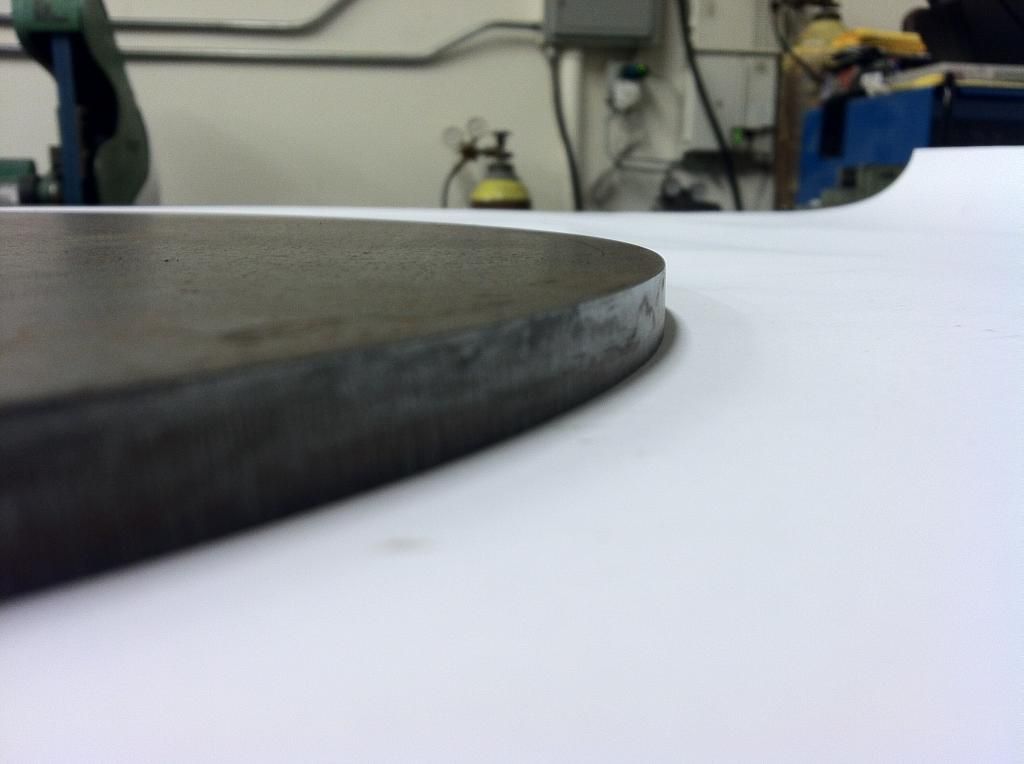

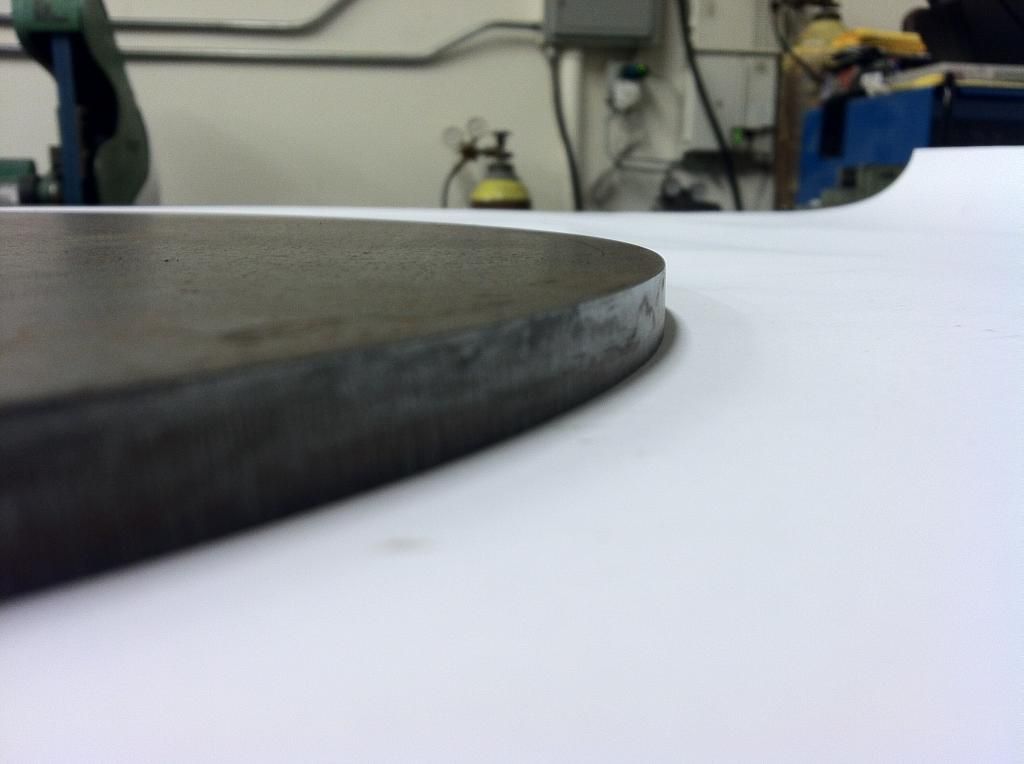

And the 3/8". It is 13.625 in DIA

Ok, so far I am happy to report that changing out the retaining cap seems to have solved the problem.

I just cut some 3/16" HRPO and it cut great.

I also cut a piece of 3/8" HRS and it was probably the best cut I've ever had on that thickness.

I still don't know what would/could go wrong with the retaining cap to warrant replacement? There is no damage, plugged orifices, or signs of wear that I can see???

Either way, it's a relatively cheap fix seeing as how I got a year of cutting out of the first cap. Thanks for the tip Stout. I owe you one.

Here are the 3/16" parts. They are only 1.5" x 2"

And the 3/8". It is 13.625 in DIA

-

Stout

- 3 Star Elite Contributing Member

- Posts: 255

- Joined: Wed Apr 29, 2009 8:14 am

- Location: Helotes, TX

Re: Problems with Hypertherm Consumables...

Just sharing the joy. Would you mind if I asked what amperage and speed you used to cut those little parts? I would really like to have the file so I can compare my machine to those very nice results. And would you mind sharing a picture of the back side?ZTFab wrote:UPDATE:

Ok, so far I am happy to report that changing out the retaining cap seems to have solved the problem.

I just cut some 3/16" HRPO and it cut great.

I also cut a piece of 3/8" HRS and it was probably the best cut I've ever had on that thickness.

I still don't know what would/could go wrong with the retaining cap to warrant replacement? There is no damage, plugged orifices, or signs of wear that I can see???

Either way, it's a relatively cheap fix seeing as how I got a year of cutting out of the first cap. Thanks for the tip Stout. I owe you one.

Here are the 3/16" parts. They are only 1.5" x 2"

Victor Simonis

Grey Forest MetalCraft

Helotes, TX 78023

210-872-2622

Sector Technologies Photon 5x10 water table machine with Hypertherm Micro Edge Controller, Powermax 105

Grey Forest MetalCraft

Helotes, TX 78023

210-872-2622

Sector Technologies Photon 5x10 water table machine with Hypertherm Micro Edge Controller, Powermax 105

-

jimcolt

- 5 Star Elite Contributing Member

- Posts: 3087

- Joined: Mon Jul 20, 2009 11:18 pm

- Location: North Carolina

Re: Problems with Hypertherm Consumables...

The retaining cap on Hypertherm Powermax systems over time can wear to a point that cut quality changes. It has critically machined air passages that meter the shield air flow.....the shield injects air radially around the plasma arc to improved energy density and edge squareness. The cap also helps to hold the nozzle, electrode and shield in concentric alignment.....so wear from a lot of use can change the required concentricity....dramatically affecting cut quality.

The cap on my (almost) four year old Powermax85 torch is the original, however I likely put a lot kless hours on it as compared to most...

Jim Colt

The cap on my (almost) four year old Powermax85 torch is the original, however I likely put a lot kless hours on it as compared to most...

Jim Colt

-

Stout

- 3 Star Elite Contributing Member

- Posts: 255

- Joined: Wed Apr 29, 2009 8:14 am

- Location: Helotes, TX

Re: Problems with Hypertherm Consumables...

Jim,

I'm using the Duramax MRT on my PM1250. When I change consumables I always turn on the air and put my hand under the torch to avoid splashing water. I recently noticed that air is coming out of the torch body between the retaining cap the torch body. What is the purpose of this escaping air?

I'm using the Duramax MRT on my PM1250. When I change consumables I always turn on the air and put my hand under the torch to avoid splashing water. I recently noticed that air is coming out of the torch body between the retaining cap the torch body. What is the purpose of this escaping air?

Victor Simonis

Grey Forest MetalCraft

Helotes, TX 78023

210-872-2622

Sector Technologies Photon 5x10 water table machine with Hypertherm Micro Edge Controller, Powermax 105

Grey Forest MetalCraft

Helotes, TX 78023

210-872-2622

Sector Technologies Photon 5x10 water table machine with Hypertherm Micro Edge Controller, Powermax 105