1/4" holes in 3/16" steel ?

- HammerDownJustin

- 3.5 Star Member

- Posts: 614

- Joined: Mon Mar 04, 2013 10:41 pm

- Location: Paradise,Tx

1/4" holes in 3/16" steel ?

Going to be a few days before I get my 3/16" back on the table. Any suggestions trying to cut 1/4" holes in 3/16" or am I dreaming. Would drill them but got afew odd measurements. Thought about adding a couple line cuts towards the edges then just lay a straight edge down and draw lines and drill them afterwards instead. Hypertherm 65 is the source and machine is pretty damn accurate. I have done 1/2" holes in 1/2" plate that came out good.

Home built 5x10 table CandCNC electronics

Miller 251 Mig

And lots of other cool stuff...

Miller 251 Mig

And lots of other cool stuff...

-

I Lean

- 3 Star Member

- Posts: 394

- Joined: Sun Jan 02, 2011 11:03 pm

Re: 1/4" holes in 3/16" steel ?

I'd pierce-mark the hole centers, then just drill them.

- HammerDownJustin

- 3.5 Star Member

- Posts: 614

- Joined: Mon Mar 04, 2013 10:41 pm

- Location: Paradise,Tx

Re: 1/4" holes in 3/16" steel ?

Been running for a year now and never tried to pierce mark. What would be the best way to go about that with corel and sheet cam? Maybe a circle like .000069 or something?

Home built 5x10 table CandCNC electronics

Miller 251 Mig

And lots of other cool stuff...

Miller 251 Mig

And lots of other cool stuff...

- HammerDownJustin

- 3.5 Star Member

- Posts: 614

- Joined: Mon Mar 04, 2013 10:41 pm

- Location: Paradise,Tx

Re: 1/4" holes in 3/16" steel ?

The one I did before I tried to just cut 2 cross lines and drill the center but as I am sure most know here that it did not turn out well.

Home built 5x10 table CandCNC electronics

Miller 251 Mig

And lots of other cool stuff...

Miller 251 Mig

And lots of other cool stuff...

-

I Lean

- 3 Star Member

- Posts: 394

- Joined: Sun Jan 02, 2011 11:03 pm

Re: 1/4" holes in 3/16" steel ?

Just draw the holes in your drawing whatever size you want. In Sheetcam, put all those holes on their own layer. (named "Pierces", or whatever you like) Create a new cutting tool. (mine is called "Drill Spot") Mine uses .15" pierce height, .15" cut height, and 0 pierce delay.

Use the "drill" function in the operations, select your Pierces layer, make sure the min hole size is smaller than your holes, and the max is larger. Then set up the rest of the cut like you normally would. If you do it all right, it should go through and pierce all the hole centers, then cut the part out. Under "Nesting", make sure you select "keep parts together", otherwise it will want to pierce all the holes of all the parts before cutting any of them.

Use the "drill" function in the operations, select your Pierces layer, make sure the min hole size is smaller than your holes, and the max is larger. Then set up the rest of the cut like you normally would. If you do it all right, it should go through and pierce all the hole centers, then cut the part out. Under "Nesting", make sure you select "keep parts together", otherwise it will want to pierce all the holes of all the parts before cutting any of them.

- HammerDownJustin

- 3.5 Star Member

- Posts: 614

- Joined: Mon Mar 04, 2013 10:41 pm

- Location: Paradise,Tx

Re: 1/4" holes in 3/16" steel ?

Thank you sir..I will try this out.

Home built 5x10 table CandCNC electronics

Miller 251 Mig

And lots of other cool stuff...

Miller 251 Mig

And lots of other cool stuff...

- HammerDownJustin

- 3.5 Star Member

- Posts: 614

- Joined: Mon Mar 04, 2013 10:41 pm

- Location: Paradise,Tx

Re: 1/4" holes in 3/16" steel ?

should I zero anything else out? Maybe the plunge rate needs to be different and zero the speed?

Home built 5x10 table CandCNC electronics

Miller 251 Mig

And lots of other cool stuff...

Miller 251 Mig

And lots of other cool stuff...

-

I Lean

- 3 Star Member

- Posts: 394

- Joined: Sun Jan 02, 2011 11:03 pm

Re: 1/4" holes in 3/16" steel ?

Plunge rate doesn't matter, if you make your cut height the same as your pierce height. The goal is to get the shortest possible "crack" of the plasma. Also, don't set it up as a cutting operation, use the drill instead of jet cutting. That will mark the centers of the holes instead of cutting the outline of it.

- HammerDownJustin

- 3.5 Star Member

- Posts: 614

- Joined: Mon Mar 04, 2013 10:41 pm

- Location: Paradise,Tx

Re: 1/4" holes in 3/16" steel ?

Yes sir thank you very much. Didnt see the drilling function on my sheet cam but fixing to look again

Home built 5x10 table CandCNC electronics

Miller 251 Mig

And lots of other cool stuff...

Miller 251 Mig

And lots of other cool stuff...

- HammerDownJustin

- 3.5 Star Member

- Posts: 614

- Joined: Mon Mar 04, 2013 10:41 pm

- Location: Paradise,Tx

Re: 1/4" holes in 3/16" steel ?

Okay found it up in the operations bar.Went back to my tool and changed the cut height to match the pierce height at .15 . Then went up top and set up a drilling operation and picked that tool. Set the minimum hole size to 0 and max to 1". Cut path is also on auto and set to start in the center.

Home built 5x10 table CandCNC electronics

Miller 251 Mig

And lots of other cool stuff...

Miller 251 Mig

And lots of other cool stuff...

-

I Lean

- 3 Star Member

- Posts: 394

- Joined: Sun Jan 02, 2011 11:03 pm

Re: 1/4" holes in 3/16" steel ?

Sounds like you've got it....keep us posted on how it works for you.

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: 1/4" holes in 3/16" steel ?

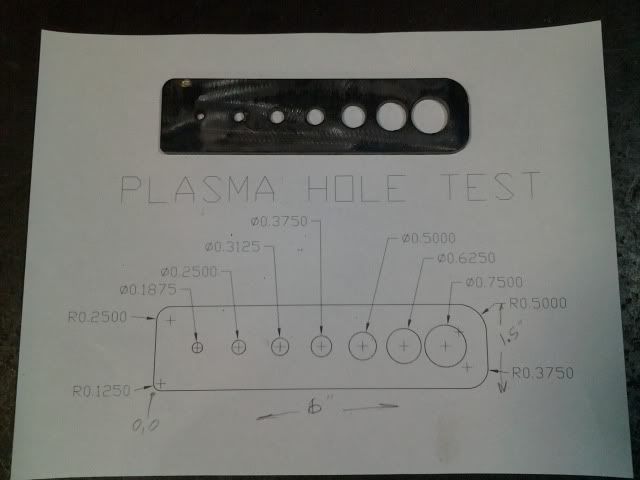

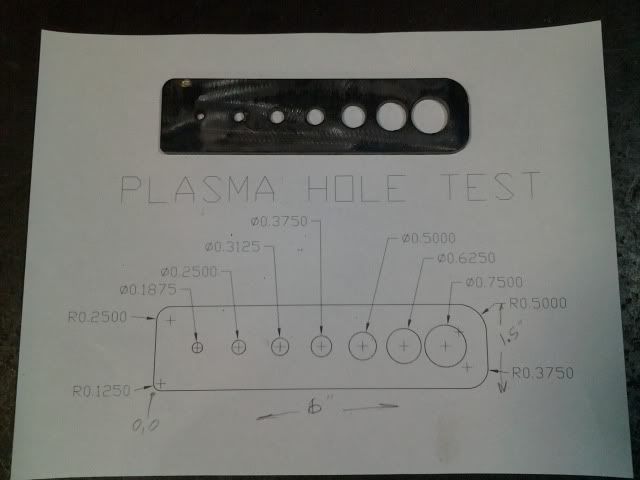

those holes should be doable with plasma. do a test cut in 3/16 plate using the inside offset in sheetcam. measure a couple of holes for quality and adjust the kerf width in sheetcam to get your holes right on size.

ie, if your hole is undersized using the hypertherm cut chart, narrowing the kerf width in sheetcam will lessen the offset and make your hole bigger.

i did this in 10 ga steel, even the 1/8 hole came out fine, .125 hole in .140 steel

ie, if your hole is undersized using the hypertherm cut chart, narrowing the kerf width in sheetcam will lessen the offset and make your hole bigger.

i did this in 10 ga steel, even the 1/8 hole came out fine, .125 hole in .140 steel

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- HammerDownJustin

- 3.5 Star Member

- Posts: 614

- Joined: Mon Mar 04, 2013 10:41 pm

- Location: Paradise,Tx

Re: 1/4" holes in 3/16" steel ?

You got a 1/8" hole in 3/16"? That is pretty damn good. Yep I do .20 holes all the time in 14g but just figuring 3/16" was pushing it for 3/16" but I bet I drill them because they haft to be perfect. Will be my new Gantry plates for mounting the bearing on my new table..lol

Home built 5x10 table CandCNC electronics

Miller 251 Mig

And lots of other cool stuff...

Miller 251 Mig

And lots of other cool stuff...